Early Müller-Philips “Metalix” Tube (Type D)

|

|

|

|||

|

|

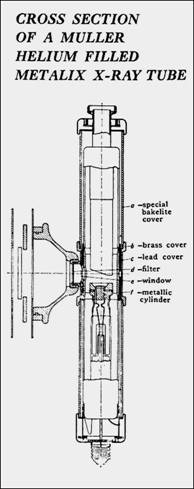

Designed

in the mid-twenties by Pr. Albert Bouwers of the

Philips Company, in This tube of the “Coolidge Type” built

on the Media Line Focus principle was

initially sold under the brand name of “Müller

Media-Metalix” and later as “Philips

Metalix”. Its cylindrical central part (the canister) was made of

chrome-steel alloy, fused on either side to the glass tubing forming the rest

of the body of the tube. The canister is surrounded by a protective layer of

lead covered by the exterior visible metal parts. X-rays come out of the tube through a round

glass window fused to the center of the canister, and then through an

aluminium filter. A thick cylindrical housing, of what is described as

“special bakelite” protects the rest of the tube. Unfortunately this tube was received broken.

But looking inside, the glass seemed too fragile for the disproportionately

heavy anode. The tungsten target embedded in

copper is at a low angle, and the focal spot is a virtual 3mm square. This particular

tube is water-cooled, but similar tubes were also sold with metal radiators. Some tubes were even jet-air cooled (Go to“Philips Metalix Tube”). |

|

||

|

|

This “Type D” tube boasted 100 mA at up to 70 kVp and 40 mA up to 100 kVp (for short

exposures only), or 6 mA at 125 kVp

continuously. Later models of the “Metalix” were

better protected, larger in size and with an improved output, and were even manufactured

in different parts of the world. To the left are two old advertisements of

the Metalix tube, one under the name of “Müller-Media-Metalix”, water-cooled, and the other under

the name of “Philips-Metalix”, with a metal

radiator. |

|||

|

In order to go around the G.E. Coolidge

patent covering hot cathode tubes in vacuum, the Metalix tube had a Helium

filling at a pressure of at

least 1/1000 mm of Mercury. This Helium inclusion had practically no effect

on the efficiency of the tube and soon

diffused out of its glass wall. |

||||

| Go to Category Index | ||

| Go to Main Page |